Sewage Treatment Case Study

Parameters:

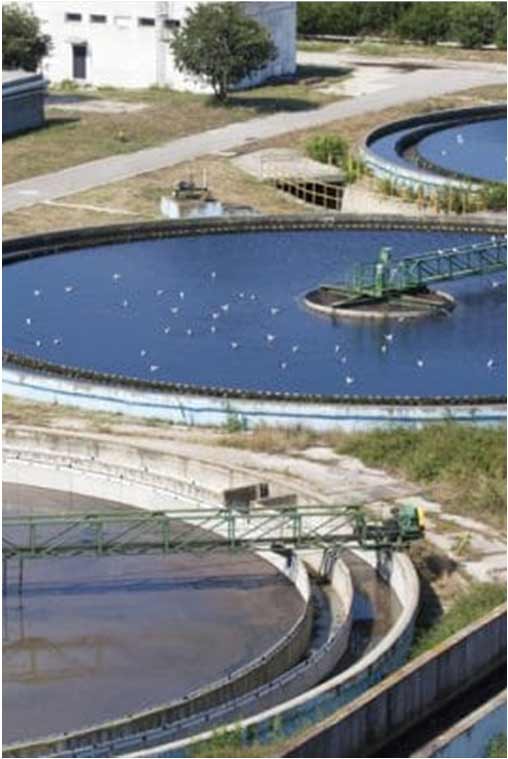

Sewage treatment facility in California, USA

Population 89,000

Plant processes 7 million gallons per day of wastewater

Problem:

High levels of : HS (hydrogen sulfide), TSS (Total suspended solids) and BOD (Biological Oxygen Demand (BOD), Frequent overflows, fouls odors and corrosion of treatment tanks.

Trial:

Drainteks solution was used for 90 days

Application:

Added directly to pump station at 2.0 ppm flow

H2S, BOD and TSS concentrations analyzed for 3 months

Results:

Since corrosion of the tanks is known to be caused by acids formed by the increase of hydrogen sulfide, a 98.5 % reduction of H2S is guaranteed to stop further corrosion.

- H2S went from 100 ppm to 1.5 ppm – 98.5% reduction

- BOD went from 115mg/l to 22 mg/l – over 80 % reduction

- TSS went from 188 mg/l to 30 mg/l- over 84% reduction

NYC Hospital Case Study

Parameters:

Here is an example of a well known hospital in New York City that saved enormous amounts of money in their grease trap and drain maintenance.

Problem:

The majority of over $500,000 per year expenses were incurred by continuously clogged and damaged pipes – caused by sewage and grease buildup. The vents spewed foul sewage odors into the patient’s rooms.

Results:

In its first year of using Drainteks , a 510 bed hospital in New York City saved close to 500,000 dollars in its yearly plumbing and repair costs. Two years later, the yearly drainage system costs were an average of 10,000 dollars per year -that is 2 % of the former cost – or a 98 % saving! Now the doctors, patients and employees are in a more healthy environment–with no more foul odors.